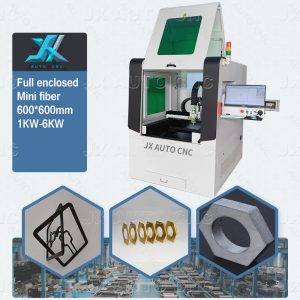

Price Range : $6100/ Set based on the configuration

Brand : Jx Auto CNC

Model :JX-2030

Category : CNC Metal Cutter-Fiber Cutter

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability : 200 Sets In Stock / Month

Policy : Shopping, Return, Refund Policy

Description :

Mini fiber laser cutter can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber ,it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing.

1. Strong stability, high precision, and with no deformation for 20 years

The carbon steel structure has good toughness, excellent ductility, and great welding and heat treatment performance. Besides, the stress annealing and vibration aging function are used to deal with the stress in the welding and machining process of the machine tool, so that the machine is more durable.

2. High precision linear motor

Adopts a high-precision linear motor, which has the features of compact structure and low power consumption. In addition, there is

No mechanical contact and less friction. Moreover, it has the advantages of smooth motion, high positioning and repositioning accuracy, high speed and acceleration, fast response, high sensitivity, excellent tracking performance, low noise, high efficiency, and good cutting quality.

3. Cast aluminum beam

After artificial aging and solution treatment, it has good integrity, high rigidity, great surface quality, high toughness and ductility, etc. The aluminum alloy has light weight and strong rigidity, which is conducive to high-speed movement and high-precision cutting of various graphics during the fast laser cutting process.

| standard configuration | ||

| Item | Subitem | JX2030 |

| Basic parameter | Working area | 200*300mm |

| Table load bearing | 60kg | |

| Machine overall dimensions | 950*820*780mm | |

| Machine weight | 220kg | |

| Z axis travel | 100mm | |

| Operation parameter | Max. linkage speed | 50m/min |

| Max. acceleration | 0.5G | |

| Positioning accuracy | 0.03 | |

| Repositioning accuracy | 0.02 | |

| processing precision(1 mm Original box carbon steel plate) | Φ30mm roundness | ≤0.1mm |

| □30mm adjacent side dimension difference | ≤0.04mm | |

| 190mm adjacent side dimension difference | ≤0.05mm | |

| 190mm diagonal size difference | ≤0.07mm | |

| Optical system | Laser source | Max/Raycus/JPT |

| laser head | Raytool | |

| mechanical system | Machine bed | Integrated welding |

| X-axis 、Y-axis 、Z-axis Servo motor and driver | Fuji | |

| slideway | Taiwan Hiwin | |

| Countertop locking function | Fixed table top (manual clamp table top) | |

| Intelligent control system | Control system | Raytool EDS3000 |

| WI FI wireless contro | · | |

| Laser cutting technology database | · | |

| Auxiliary gas low pressure alarm function | · | |

| Cutting gas | nitrogen | |

| Low voltage electrical appliances | Honeywell | |

| System identification file format | DXF 、DWG 、PLT 、ENG G file 、 DXF 、 DWG 、 PLT 、 ENG | |

| Gas low pressure alarm | · | |

| Water cooler abnormal alarm | · | |

| Water cooler | · | |

| Dust removal | Centrifugal fan | |

| Other parameters configuration | Multifunctional ergonomic handle | · |

| Total power capacity/current wit 1 KW source | 40KVA/183A | |

| Total power capacity/current with 1.5 KW source | 48KVA/220A | |

| Consume | Mirror /nozzle | |

1、I need a CNC router, can you give me some suggestions?

A : Sure, we will give suggestions of the most suitable machine. Before that, we need to know some information, such as effective processing area, materials, etc., to determine the main parameters.

2. Which kind of materials can be processed on this machine?

A: Wood, mdf, stone, acrylic, glass, plastic, foam, aluminium, copper.

and almost all kinds of non-steel materials.

3. Are you a factory or trading company?

A : We are the manufacturer and we have 10 years factory experience As only the machine made by ourself, the quality can be trusted, and the most important thing is that we can do better after-sales service We know how to fix the problem of every part easily, so welcome to visit to our factory.

4.How should I pay for my order ?

A : You need to pay 30% as prepayment at first, then we will start to make production. When the machine is completed, we will send pictures or videos to you, and then you need to pay the balance.We will ship the machine to you after we receive your full payment.

5.How long is the delivery time?

A : For standard machines it will be 7-10 days: For non-standard machines and customized machines according to clients’ specific requirements. it will be 15 to 30 days.

Mini Laser Metal Jewelry Cutter for Silver Gold Copper, It is widely used for carbon steel, stainless steel, aluminum and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry.