Price Range : $6000/ Set based on the configuration

Brand : Jx Auto CNC

Model : JX-1625

Category : Cloth CNC-CCD Vibration

Payment: TT, Visa, Mastercard, Credit Cards, Paypal

Supply Ability : 200 Sets In Stock / Month

Policy : Shopping, Return, Refund Policy

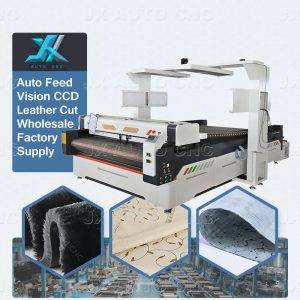

CNC camera with projector recognize cutter ,this machine is firstly take a picture for the material ,load to system identify set the damage flaw on real leather ,then let the projector to projection bypasses defects to cut specified patterns.This device efficiently cuts and saves genuine leather material.

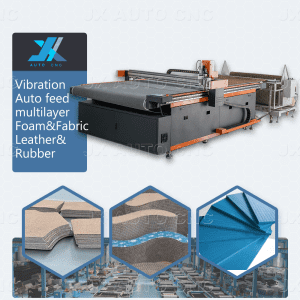

1. The JX AUTO CNC auto loading oscillating vibrating automatic garment cutting machine digital leather/cloth/fabric/textile knife cutter used for cutting sunscreen fabrics and other fabrics for blinds.

2. Using the Swiss cutting system, the cut section is straight and tidy, no fray, no scorch, no fluffy and no color fading off.

3. The cutting tool can be cut in different ways by adjusting the type of the cutter according to the thickness of the fabric.

4. Simple selection of tooling via push button, or by remote control

5. With electricity and roller feeding system

| Parameter/Model | JX-1625 |

| Working table size | 1600*2500mm |

| Rated voltage | 380V 3 phase , 220V 3 phase, 220V 1 phase |

| Table | vaccum working table, with auto conveyor table |

| Multi-functional Cutting Head | Replaceable oscillating knife |

| Safety | High sensitivity infrared induction (optional) |

| Moving Speed | Max. 1200mm/s |

| Cutting Speed | Max. 800mm/s(please set the speed according to the material) |

| Material Applicable | Corrugated paper, PVC expansion sheet, KT board, foam board,grey paperboard, cardboard, vehicle sticker, adhesive sticker etc. |

| Cutting Depth | Max 30mm (depends on the material) |

| Material Fixing Method | Strong power vacuum absorption and intelligence Partition |

| Resetting Positioning Accuracy | Max 0.01mm |

| Mechanical Precision | Max 0.02mm |

| Drive System | Steel Simultaneous Belt, Japna servo motor,HIWIN guide rail,synchronous belt, Taiwan ball screw |

| Control System | Kinco or Trocen control system |

| Operation Mode | Op worktable + data output control software (The op worktable has two type: connected and separated) |

| Display | English LCD |

| Command | HP-GL compatible format |

| Buffering Capacity | Standard–2GB |

| vaccum pump | 9KW vaccum pump |

| Knife box | 20 pieces for new customer |

| Body dimension | 3391*2423*1235mm |

1、I need a CNC router, can you give me some suggestions?

A : Sure, we will give suggestions of the most suitable machine. Before that, we need to know some information, such as effective processing area, materials, etc., to determine the main parameters.

2. Which kind of materials can be processed on this machine?

A: Wood, mdf, stone, acrylic, glass, plastic, foam, aluminium, copper.

and almost all kinds of non-steel materials.

3. Are you a factory or trading company?

A : We are the manufacturer and we have 10 years factory experience As only the machine made by ourself, the quality can be trusted, and the most important thing is that we can do better after-sales service We know how to fix the problem of every part easily, so welcome to visit to our factory.

4.How should I pay for my order ?

A : You need to pay 30% as prepayment at first, then we will start to make production. When the machine is completed, we will send pictures or videos to you, and then you need to pay the balance.We will ship the machine to you after we receive your full payment.

5.How long is the delivery time?

A : For standard machines it will be 7-10 days: For non-standard machines and customized machines according to clients’ specific requirements. it will be 15 to 30 days.