01.Transformation of glass processing

Glass is an amorphous inorganic non-metallic material, which is generally made of a variety of inorganic minerals as the main raw materials and a small amount of auxiliary raw materials. Glass materials are widely used in construction, automobiles, electronics and other fields due to their many advantages such as varied shapes, good impact resistance and controllable costs.

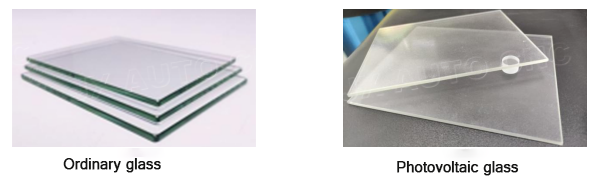

Although glass materials have many advantages, they are brittle materials and are prone to cracks and rough edges during processing. In addition, glass of different thicknesses and different applications (such as photovoltaic glass) have different requirements for processing technology. Therefore, how to improve the cutting quality of glass has become a common goal in the industry. With the development of laser technology, laser cutting has also been widely used in the field of glass processing.

02. Advantages of laser cutting

Traditional glass cutting

Cutting is an essential basic process in glass production and deep processing. Traditional glass cutting processes mainly include wheel cutting and CNC grinding cutting. The glass cut by the wheel has large broken edges and rough edges, and the processing quality and precision are difficult to guarantee. The subsequent maintenance process is complicated and causes increased costs. CNC has improved precision compared to the wheel, but the speed is difficult to guarantee.

Laser Cutting

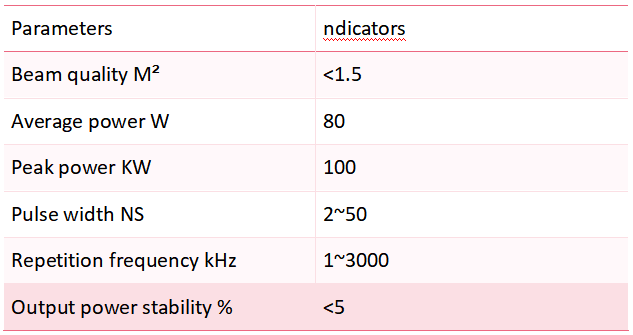

Glass is a poor conductor of heat, has a very low absorption rate for infrared rays, and has a transmittance of up to 93%. Under normal circumstances, cutting glass with a 1070nm wavelength laser basically cannot form processing, and infrared laser cutting glass requires a peak power of up to 100kW. Ultrafast picosecond lasers have long been used in glass cutting, but due to their extremely high equipment costs, they are currently mainly used in 3C, display and other fields, and are difficult to promote on a large scale. Guangzhi Technology has launched the GT series lasers with high beam quality and high peak power and adjustable pulse width for glass hole cutting, which are highly efficient and effective. Compared with ordinary lasers, it has a shorter pulse width, higher peak power and greater power density. High-energy-density high-peak lasers acting on glass can quickly destroy the damage threshold of the glass and achieve the processing effect. High-peak power lasers used in glass hole cutting have the advantages of small taper, high precision, small edge collapse, no consumables, and maintenance-free. They are also easy to integrate and suitable for automated production.

03. Laser cutting measurement

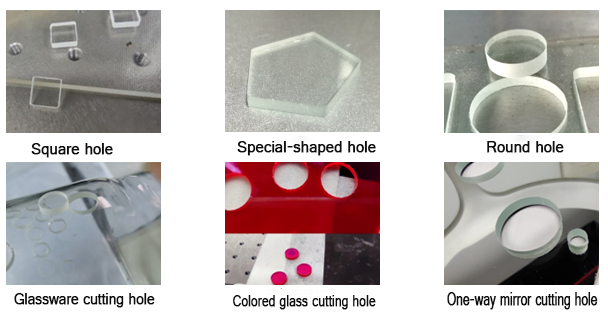

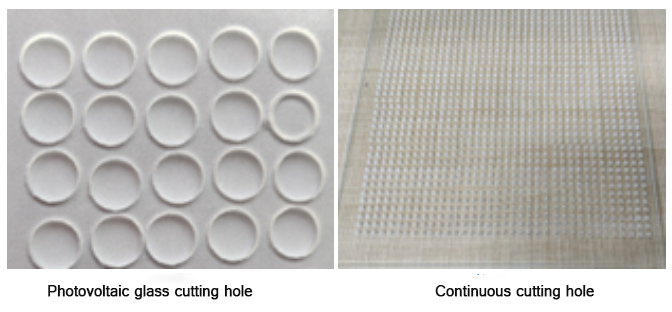

Test 1: Use F-80-GT-10-N3 laser to test hole cutting on different glass materials. Tests were performed on round and non-round hole cutting on household ordinary flat glass, photovoltaic glass, single-sided frosted glass, mirror glass, colored glass, molded glass containers and other light-transmitting glass. The results show that F-80-GT-10-N3 can be used to cut holes in a variety of glass materials, and can flexibly design the cutting shape. After cutting, the inner wall of the hole is clean, with basically no dust residue, low glass damage, and the edge collapse can be as low as 200μm, with high efficiency.

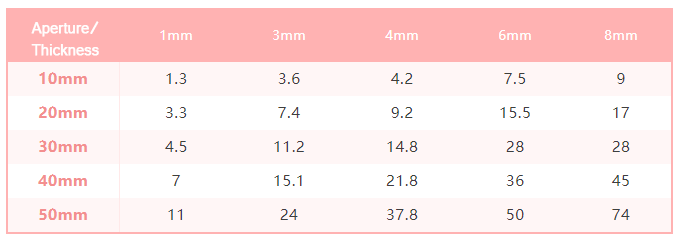

Test 2: Use F-80-GT-10-N3 to conduct hole cutting tests on ordinary glass of different thicknesses, and sort out the cutting time of different hole diameters for reference. Compared to mechanical drilling, laser cutting has very significant advantages.

04.Optimize laser

F-80-GT-10-N3

The average power range of the GT series lasers of Guangzhi Technology is 80~200W. It can cut holes in different glass materials with a minimum cutting aperture of 0.5mm, and is not restricted by the cutting shape. It has high quality and fast speed. Guangzhi Technology has cooperated with many glass processing manufacturers. In the future, Guangzhi Technology will continue to increase its research and development efforts, and continuously optimize the performance of lasers based on feedback from merchants to provide everyone with better quality lasers.