To select a suit fiber laser cleaning machine ,should learn about fiber laser cleaning machine source type.

Fiber laser cleaning machines on the market are divided into pulse type and continuous type.

1.Pulse fiber laser cleaning type is usually 100W and 200W;

2.Continuous fiber laser cleaning type machine is usually 1000W, 1500W and 3000W.

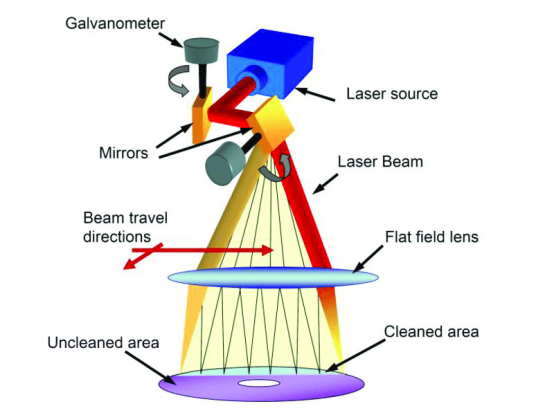

The fiber laser cleaning machine working principle difference:

1-Pulse laser cleaning machine: Pulse laser cleaning machine outputs laser beam in the form of pulses.Each pulse has high energy and high instantaneous power. Pulse laser cleaning uses high-energy laser pulses to instantaneously irradiate, producing a laser striking effect that peels off or breaks dirt.

2-Continuous laser cleaning machine: Continuous laser cleaning machine cleans by continuously outputting a laser beam. The laser beam continuously irradiates the target surface and evaporates or ablates dirt through thermal effects.

For example, the 3000W laser cleaning machine equipment is suitable for cleaning when the rust layer, paint layer is thick, and the oil stain is deep, as well as for surface roughening, weld cleaning and other processes. The 3000W laser cleaning machine has larger power, faster cleaning speed and higher efficiency.

Two kind fiber laser cleaning machine application s:

1-Continuous laser cleaning machine: suitable for cleaning light dirt attached to the surface, such as paint, grease, dust, etc., and suitable for cleaning large areas of flat surfaces.

2- Pulse laser cleaning machine: It is suitable for treating dirt that is difficult to clean, such as oxide layers, coatings, welding slag, etc. It is more suitable for cleaning tasks with fine parts or high surface quality requirements.

Selecting the power of the pluse fiber laser cleaning machine needs to consider the material to be descaled, the surface state, the descaling requirements and other factors, generally speaking, the laser descaling machine with a power between 50W and 500W can be applied to most industrial scenarios.

Fiber laser cleaning machine power selection factors consider following:

1.Rust removal materials: different materials have different power requirements. Generally speaking, metal surface descaling needs higher power, while for non-metallic materials, such as wood, fabric, etc., the power can be relatively low.

2.Surface state: the degree of surface pollution, oxidation degree, etc. will affect the power selection. For example, for metal with serious surface pollution, higher power is needed.

3.Rust removal requirements: the requirements of rust removal will also affect the power selection. If you need to remove a deeper layer of oxidation, or for a larger area of rust removal needs, need a higher power.

Generally speaking, continuous fiber laser cleaning machines are suitable for cleaning large areas, while pulse fiber laser cleaning machines are suitable for cleaning difficult-to-clean dirt and fine parts. The specific choice of which type of fiber laser cleaning machine needs to be comprehensively considered based on factors such as cleaning objects, cleaning requirements, and budget.

Cost of Continuous and pulse fiber laser cleaning machine:

With the market develop ,now pulse fiber laser cleaning machine produce cost is lower and lower ,more and more client choose the pulse fiber laser cleaning machine for Cleaning of heat-sensitive materials.But considering speed, large-area cleaning tasks, and applications with a high tolerance for heat-affected zones, a continuous fiber laser cleaning machine may be a better choice.